ACADEMIA

Russian scientists build model that will accelerate creation of alloys with specified properties

Scientists at the Ural Federal University have proposed a method for significantly accelerating the synthesis of aluminum-based alloys. Using computer modeling, researchers can control the internal structure of the alloy and influence its physical properties. In the process of creating the mathematical model, physicists performed unique calculations, the results of which are presented in the Journal of Physics: Condensed Matter.

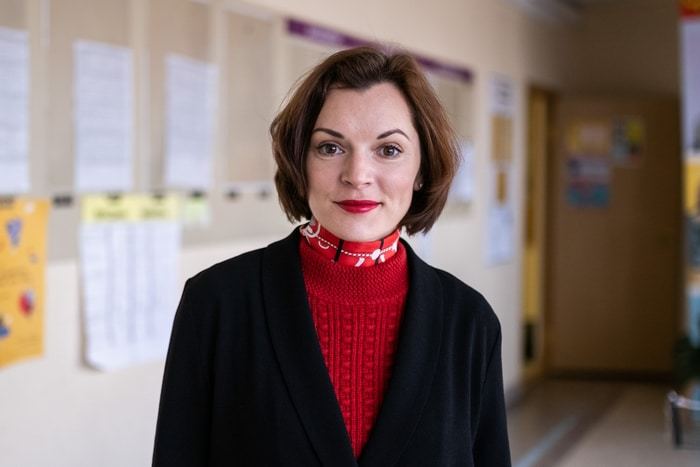

“We made calculations for silumin, an alloy of aluminum and silicon. It is actively used for casting parts in the automotive, motorcycle, and aircraft industries because of its ability to form castings without defects. We were able to develop a mathematical model to describe the different shapes of dendritic crystals formed in the alloy structure at different supercooling temperatures. The shape of the crystals in the alloy predetermines the physical properties of the materials - strength and ductility, thermal conductivity, and electrical conductivity. With the help of modeling, we can determine what shape of crystals is necessary to improve certain properties of the alloy, and produce parts with the specified characteristics,” explains Lubov Toropova, Senior Researcher at the Laboratory of Mathematical Modeling of Physical and Chemical Processes in Multiphase Media at UrFU.

The researchers verified their model at the electromagnetic levitation experimental facility at the Friedrich Schiller University Jena in Germany. The theoretical models obtained as part of the project allow described real experimental data on the kinetics of crystal growth in melts.

“The unique equipment makes it possible to conduct real experiments and describe the dendritic structure of the alloy. Additionally, we use numerical simulation methods in our calculations, with the help of which we can immediately adjust the composition and characteristics of the alloy. For example, we found that in some cases dendritic crystals growing from pure silicon evolve faster than crystals growing from silumin melt, and this improves the microstructure and properties of the final material, in other words, it is necessary to adjust the melt composition if we want to speed up the process of casting parts,” said Lubov Toropova.

According to the scientists, the mathematical models under development will allow to quickly create alloys of different metals with the necessary properties. Based on experimental studies of the model, physicists have created software and received a certificate of state registration of the computer program. The software will make it possible to simulate complex processes of structural-phase transformations that take place in alloys of different metals and to create new generation materials with improved characteristics.