PROCESSORS

Water makes wires even more nano

Rice University lab extends meniscus-mask process to make sub-10 nanometer paths

Water is the key component in a Rice University process to reliably create patterns of metallic and semiconducting wires less than 10 nanometers wide.

The technique by the Rice lab of chemist James Tour builds upon its discovery that the meniscus – the curvy surface of water at its edge – can be an effective mask to make nanowires.

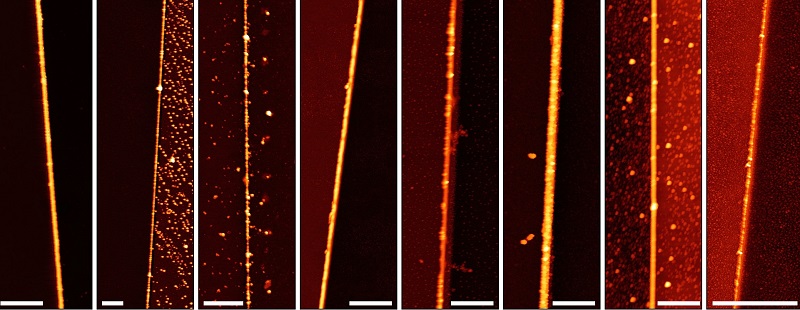

The Rice team of Tour and graduate students Vera Abramova and Alexander Slesarev have now made nanowires between 6 and 16 nanometers wide from silicon, silicon dioxide, gold, chromium, tungsten, titanium, titanium dioxide and aluminum. They have also made crossbar structures of conducting nanowires from one or more of the materials.

A paper on their technique, called meniscus-mask lithography, has been published online by the American Chemical Society journal Nano Letters.

The process is promising for the semiconductor industry as it seeks to make circuits ever smaller. State-of-the-art integrated circuit fabrication allows for signal wires that approach 10 nanometers, visible only with powerful microscopes. These are the paths that connect the billions of transistors in modern electronic devices.

"This could have huge ramifications for chip production since the wires are easily made to sub-10-nanometer sizes," Tour said of the Rice process. "There's no other way in the world to do this en masse on a surface."

Current approaches to making such tiny wires take several paths. Lithography, the standard method for etching integrated circuits, is approaching the physical limits of its ability to shrink them further. Bulk synthesis of semiconducting and metallic nanowires is also possible, but the wires are difficult to position in integrated circuits.

Water's tendency to adhere to surfaces went from an annoyance to an advantage when the Rice researchers found they could use it as a mask to make patterns. The water molecules gather wherever a raised pattern joins the target material and forms a curved meniscus created by the surface tension of water.

The meniscus-mask process involves adding and then removing materials in a sequence that ultimately leaves a meniscus covering the wire and climbing the sidewall of a sacrificial metal mask that, when etched away, leaves the nanowire standing alone.

Tour said the process should work with modern fabrication technology with no modifications to existing equipment and minimal changes in fabrication protocols. No new tools or materials are needed.

Tour is the T.T. and W.F. Chao Chair in Chemistry as well as a professor of materials science and nanoengineering and of computer science and a member of Rice's Richard E. Smalley Institute for Nanoscale Science and Technology.

The Air Force Office of Scientific Research supported the research.

How to resolve AdBlock issue?

How to resolve AdBlock issue?